The element Rhenium is number 75 on the periodic table and is one of the five traditionally defined refractory metals (Molybdenum, Niobium, Rhenium, Tantalum and Tungsten). Rhenium is a rare, silvery-white, dense element that resists corrosion and oxidation, but will eventually tarnish in an environment that contains moisture. Of all the metals only one, Tungsten, surpass Rhenium with the highest melting point. Rhenium is also among the elements with the highest density, does not have a ductile to brittle transition temperature and does not form carbides. Despite its density, Rhenium is ductile and malleable.

Rhenium exhibits excellent resistance to corrosion, resists acid attack and the mechanical effects of electrical erosion. Rhenium is beneficial as an alloying additive with other refractory metals as it greatly enhances the ductility and tensile strength of these alloys. Rhenium does not occur freely in nature, nor does it exist as a compound within a mineable mineral. It is among the rarest metals on Earth; however, it is widely spread throughout the Earth’s crust (approximately 0.001 ppm). Commercial production of Rhenium is obtained as the byproduct of refining and extraction from the flue dusts of Copper and Molybdenum smelters.

RHENIUM QUICK FACTS

- Atomic Number: 75

- Atomic Weight: 186.207

- Melting Point: 3186°C (5767°F)

- Density: 21.0 g/cm3

- Group Name: Transition Metals

Rhenium Forms and Sizes

Purchase your certified Rhenium materials from Ed Fagan Rhenium is not typically a stock item, but our foundry affiliations provide a seamless supply integration to meet the material needs of our customers. We offer cost-effective solutions for our customers who need their order cut, slit, sheared or centerless ground to exact specifications. Please call us today at 800-348-6268 to discuss your material requirements with our knowledgeable metal experts. They will gladly provide you with Rhenium availability, material lead times and our cost-efficient pricing.

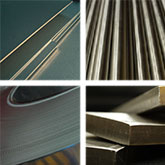

Rhenium Plate, Round Bar | Rod, Sheet, Strip | Coil

We are a distributor of Rhenium from leading mills and supply Rhenium plate, round bar, rod, sheet, strip and coil in a variety of sizes sourced from the leading mills.

Rhenium Characteristics and Properties

Rhenium exhibits numerous valuable characteristics including one of the highest melting points of all elements. View the specifications and the typical mechanical, physical, and chemical properties this metal provides.

- Good Ductility

- Good Malleability

- High Density

- High Electrical Resistivity

- Low Vapor Pressure

- Resists Acid Attack

- Resists Corrosion and Oxidation

- Resists Mechanical Effects of Electrical Erosion

Forming, Machining and Welding Rhenium

Rhenium is not machinable by conventional methods like milling and turning; however, it can be machined by ECM, EDM, abrasive cutting and grinding methods. Unlike Molybdenum, which must be heated to above its brittle-ductile transition temperature before it can be formed, Rhenium can be formed at room temperature. In addition, Rhenium maintains its ductility after recrystallization allowing it to be welded without concern for brittle weld areas.

Rhenium is not machinable by conventional methods like milling and turning; however, it can be machined by ECM, EDM, abrasive cutting and grinding methods. Unlike Molybdenum, which must be heated to above its brittle-ductile transition temperature before it can be formed, Rhenium can be formed at room temperature. In addition, Rhenium maintains its ductility after recrystallization allowing it to be welded without concern for brittle weld areas.

Rhenium Applications

Rhenium’s characteristics of high electrical resistivity over wide temperature ranges, plus a low vapor pressure makes it a good choice for filaments in mass spectrometers. Another major use of Rhenium is as a catalyst in the crack distillation of petroleum products.

The most common use of Rhenium is as an alloying agent with other refractory metals to improve their properties. When combined with Molybdenum it makes the ideal candidate for heat chokes, cathode stem supports and other similar parts due to its ductility, weldability, formability and strength. Rhenium is also found in high-temperature superalloys that are used to make jet engine parts.

- Alloying Agent with Refractory Metals

- Cathode Cups

- Grid Heaters

- Mass Spectrometer Filaments

- Nuclear Reactors

- Semiconductors

- Thermocouples

For more information on technology, engineering, and advanced materials applications, you can visit the IEEE website, one of the largest technical professional organizations worldwide.

ED FAGAN INC. supplies the highest quality special purpose metals and alloys for Aerospace/Aviation, Defense, Electronics, Magnetic, Medical, Lighting, Optical, Telecommunications, Ceramics, Heat Treating, and other high-technology industries.