Ed Fagan is a leading distributor and manufacturer of high-density Tungsten Heavy Metal Alloys (ASTM B777-15). Tungsten Heavy Alloys (WHA) are produced by powder metallurgy techniques. A range of Tungsten powder between 90% and 97% (depending on the final density required) is mixed with nominal amounts of Nickel, Copper or Iron elements and then compressed. The final phase, liquid sintering, results in four classes of high-density, machinable Tungsten-Nickel-Iron or Tungsten-Nickel-Copper Alloys with unique physical properties, as well as magnetic and non-magnetic compositions.

Overall WHA exhibit extremely useful property benefits such as, high tensile strength, good ductility and hardness. Twice as heavy as Steel and approximately 50% denser than Lead, these alloys are utilized where a concentrated mass is required in a limited space. Tungsten Alloys are relatively easy to machine and can be plated or painted to enhance their corrosion protection. Tungsten Alloys are also known as Densalloy®, Densimet®, Mallory 1000 and Fansteel 77.

TUNGSTEN HEAVY ALLOYS QUICK FACTS

- Alloyed with Ni & Fe, or Ni & Cu for Magnetic or Non-Magnetic Grades

- Complex Parts or Components Can Be More Efficiently Produced

- Environmentally Friendly

- High Density Range of 17.0 to 18.5 g/cc

- Superior Machinability Versus Pure Tungsten

Tungsten Heavy Alloys Forms and Sizes

Since Tungsten has the highest melting point of all metals (6180°F/3420°C) casting Tungsten Alloy components or parts is not possible, therefore Tungsten Heavy Alloys (WHA) are produced by powder metallurgy techniques which has size limitations. Customers often provide diagrams and schematics and the parts are supplied as semi finished products, ROTF (rough oversized to finish). The powder metallurgy techniques used in the fabrication process, allows customers to have shapes and parts formed to minimize the cost of the final product.

Ed Fagan is a leading supplier of refractory metals and alloys. You can rely on our expertise to provide you with Tungsten Alloys in the forms and shapes you need. In addition, our in-house fabrication services are available to machine your order to your size and shape requirements.

Tungsten Heavy Alloys Round Bar Rod

Tungsten Alloys are available in Round Bar/Rod in diameters starting at 0.125″ up to 3.000″ in lengths of 8.0″ to 12.0″ long, and conforms to ASTM B777-15 standards.

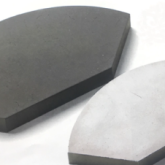

Tungsten Heavy Alloys — Parts, Plate, Shapes, Sheet

Tungsten Alloys are available in a variety of forms including Parts, Plates, Shapes and Sheets. All Tungsten Alloy forms conform to ASTM B777-15 standards.

Tungsten Heavy Alloys Characteristics and Properties

View the specifications, chemistries and all the typical mechanical and physical properties these unique alloys provide.

- Densities of 17.0 to

18.5 g/cc - High Absorption Capacity for X-rays and Gamma Rays

- Very Good Mechanical Properties

- High Young’s Modulus

- Good Corrosion Resistance

- No Toxicity

- Harmless to Health

- High Thermal Conductivity

- Low Coefficient of Thermal Expansion

Machining Tungsten Heavy Alloys

Tungsten is alloyed with different elements such as Nickel, Copper and Iron to produce a large variety of Tungsten Alloy grades. Many of these grades have engineering properties similar to Steel making them relatively easy to machine. These alloys can be drilled, milled, turned and tapped using standard tools and equipment, while using speeds and feeds similar to Grey Cast Iron.

Tungsten is alloyed with different elements such as Nickel, Copper and Iron to produce a large variety of Tungsten Alloy grades. Many of these grades have engineering properties similar to Steel making them relatively easy to machine. These alloys can be drilled, milled, turned and tapped using standard tools and equipment, while using speeds and feeds similar to Grey Cast Iron.

Tungsten Heavy Alloys Applications

Ed Fagan is a leading source for industrial supply chain distribution of Heavy Metal Tungsten Alloy grades for fabrication and parts applications within various advanced technology industries. With a nominal Tungsten content range from 90% to 97% and the balance primarily of Nickel, Copper and Iron, these alloys provide unique engineering properties. They deliver greater ductility and better machinability than pure Tungsten. Tungsten Alloys can be plated or painted to enhance their corrosion protection.

Counterbalance Weights | Vibration Dampening

- Aircraft Control Surfaces

- Automotive Suspension Systems

- Cell Phones

- Engine Components

- Golf Club Weights

- Helicopter Rotor Systems

- Racing Industry

- Ship Ballasts

Radiation Shielding Components

- Collimators

- Medical Diagnostic Equipment

- Medical Radioisotope Storage Cabinets, Syringe Housings and Vials

- Nuclear Testing Equipment

- Oil Well Logging Instrumentation

- Shielding Blocks

For more information on technology, engineering and advanced materials applications, you can visit the IEEE website, one of the largest technical professional organizations worldwide.

Ed Fagan is a leading supplier of specialty metal and alloys for manufacturers in the Aerospace/Aviation, Defense, Electronics, Energy, Magnetic, Medical, Lighting, Optical, Research, Telecommunications and other high-technology industries.