Molybdenum TZM (TZM) chemistry contains 0.40-0.55% Titanium, 0.06-0.12% Zirconium, a trace (0.01-0.04%) of Carbon for carbide formations and with the balance consisting of pure Molybdenum. TZM is manufactured by powder metallurgy techniques with the addition of particle-strengthened carbides and oxides to inhibit grain growth at elevated temperatures. This combination increases the ductility and creep strength of the alloy. TZM has a higher recrystallization temperature (1400°C) than unalloyed Molybdenum which decreases the likelihood of embrittlement at elevated temperatures.

When operating at the higher temperatures seen in many vacuum furnace and other high-temperature applications, TZM offers increased hardness, better creep resistance and ductility, and possesses approximately twice the tensile strength of pure Molybdenum. In addition, TZM exhibits good thermal conductivity, low vapor pressure, good corrosion resistance and is machinable.

MOLYBDENUM TZM QUICK FACTS

- High Melting Point at 2623°C

- More than 10 Times the Creep Resistance than Pure Mo

- Higher Recrystallization Temperature than Pure Mo

- Higher Strength and Hardness than Pure Mo

- Operating Temperatures of 1000°C to 1400°C

Molybdenum TZM Forms and Sizes

Ed Fagan is a leading supplier of refractory metals and alloys. Customers rely on our inventory of quality TZM alloys to be available from stock when needed with ease of selecting the option to fabricate their order to specification.

Molybdenum TZM Plate

Ed Fagan stocks Molybdenum TZM plate in thicknesses ranging from 0.250” to 0.625”. Our plates conform to ASTM B386 Type 364 standards.

Molybdenum TZM Round Bar | Rod

Round bar/rod is in-stock and ready to ship. Our rods are available from 0.125” to 4.720” diameters in a variety of random lengths and conforms to ASTM B387 Type 364 standards.

Molybdenum TZM Sheet

Molybdenum TZM sheets conform to ASTM B386 standards and are stocked in thicknesses starting at 0.039” to 0.118”. Ready to ship or custom cut your order.

Molybdenum TZM Characteristics and Properties

Molybdenum TZM alloy offers several advantages over pure Molybdenum. See all the pertinent material characteristics and specifications for TZM.

- Approximately Twice the Tensile Strength of Mo

- Density 10.22 g/cm3

- For Applications with Demanding Mechanical Loads

- Good Ductility at Room and Elevated Temperatures

Machining Molybdenum TZM

Molybdenum TZM can be machined by all the common metal machining processes and requires no special equipment or procedures to produce parts with accurate dimensions and excellent finishes. TZM may be machined to achieve simple parts, very complex parts, shapes and very small intricate parts.

Molybdenum TZM can be machined by all the common metal machining processes and requires no special equipment or procedures to produce parts with accurate dimensions and excellent finishes. TZM may be machined to achieve simple parts, very complex parts, shapes and very small intricate parts.

Learn about the tools, lubricants and machine settings recommended for sawing, shearing, turning, milling, shaping, reaming, threading, grinding, buffing and honing; as well as techniques for electro-polishing and photo-etching.

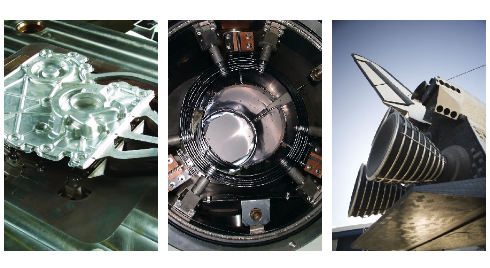

Molybdenum TZM Applications

Molybdenum TZM is used in high temperature applications involving demanding mechanical loads. TZM is appropriate for temperature use in the range of 1000°C-1400°C. In contrast to pure Mo, TZM has a higher strength, higher recrystallization temperature and improved creep strength. Below are some application examples.

- Die Inserts for Casting Aluminum

- Electrodes

- Hot Stamping Tools

- Rocket nozzles

- Rotating Anodes for X-ray Tubes

- Structural Furnace Components

- Vacuum Furnace Hearths

Due to its exceptional performance in high temperature applications, Molybdenum TZM is used extensively in the commercial heat treating industry. For more information on this industry, you can visit the ASM Heat Treating Society — the world’s largest network of heat treating professionals.

ED FAGAN INC. supplies the highest quality special purpose metals and alloys for Aerospace/Aviation, Defense, Electronics, Magnetic, Medical, Lighting, Optical, Telecommunications, Ceramics, Heat Treating, and other high-technology industries.